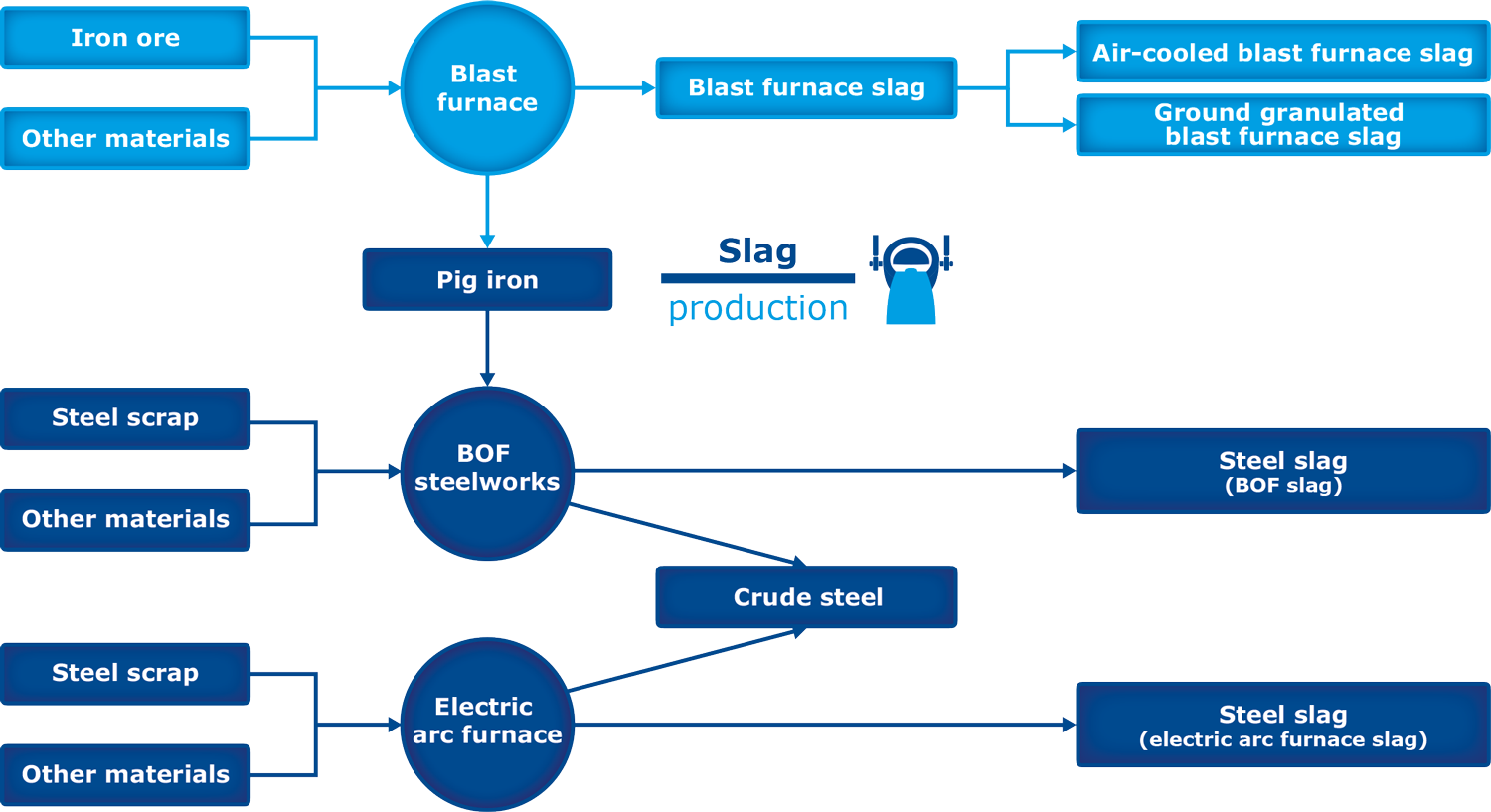

Long ago, when ironworking was just beginning, slag had to be beaten off the metal; and the German word for “beating” is “schlagen”. Today, modern processes are used to produce slag. Here we differentiate between blast furnace slag and steel slag:

Blast furnace slag is produced when iron ore and other technical additives are used to produce pig iron, and later steel. Depending on the type of cooling, this turns into crystalline air-cooled blast furnace slag or glassy ground granulated blast furnace slag.

Steel slag is produced during the manufacturing of steel from pig iron, scrap steel and other materials. Depending on the manner of processing, four different types of steel slag are distinguished: BOF slag (basic oxygen furnace), electric arc furnace slag and stainless steel slag (electric arc furnace), and secondary metallurgical slag.

As an industrially manufactured stone, slag is a “gift” that numerous industries have long appreciated. Once processed using state-of-the-art methods, products containing slag not only easily withstand comparison with other products, they even have a further advantage: slag protects nature and the environment!